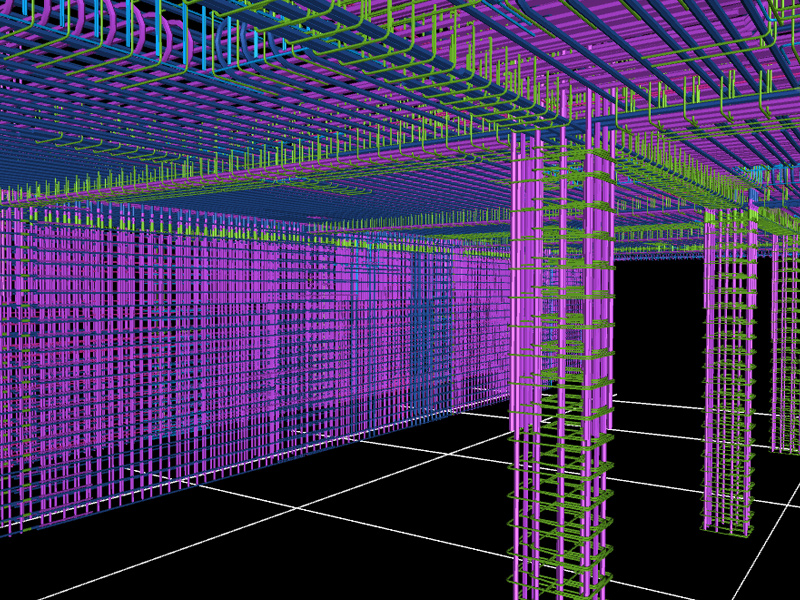

A-Grade office & retail space in prime Newcastle CBD location. Construction commenced August 2020, and completion early 2022.

At the heart of the whole Hunter Construction Group is a desire to provide a type of quality that others lack. This quality offering is all encompassing. From our first contact with potential clients and partners, Hunter Precast set out to offer the highest levels of service and communication.

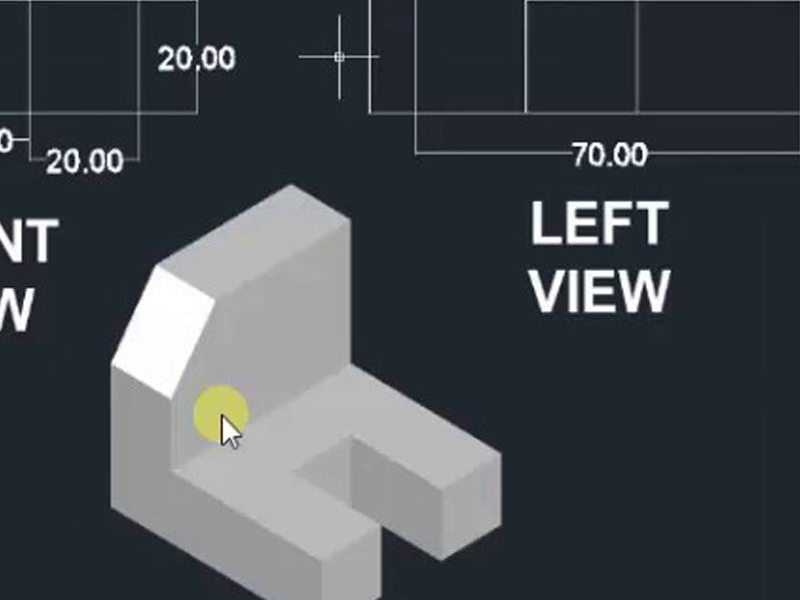

Prompt responses, quality design and engineering, fit for purpose products and professional installation services are some aspects of what you can expect.